Have you ever wondered if HydraSleeves can be used in geothermal environments? It's been asked of us numerous times; and yes, they have actually worked for some geothermal applications in South American of which we are aware.

yes, they have actually worked for some geothermal applications in South American of which we are aware.

We recently wanted to see exactly what the limitations are for HydraSleeves in heated environments. We know the specifications for our proprietary virgin food/medical grade LDPE material are stated to have a high end temperature range of 90 degrees Celcius with a melting point of 150 degrees C. This translates to 194 degrees Fahrenheit and melting at 302 degrees F. Basically our experiments found this to be true when heated without pressure. However, when dealing with extremely deep wells where heat can play a factor, there can also be a lot of pressure. So, does pressure along with heat change the specs of HydraSleeve use?

Let us see:

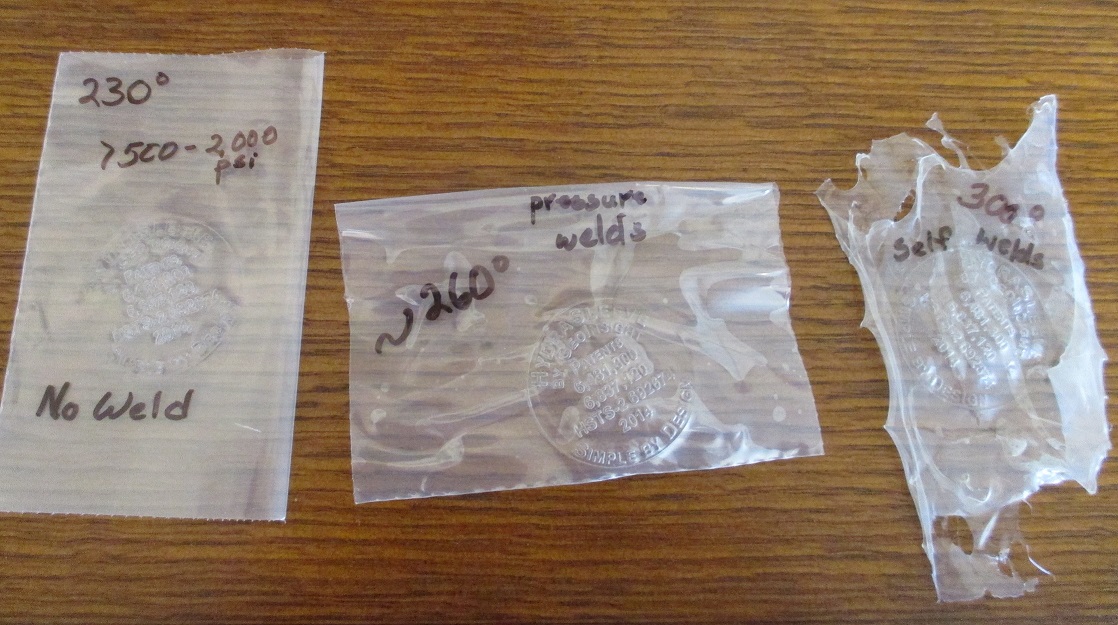

- We boiled the sleeve in water for 10 minutes and immediately removed it and put in in the vice. Although the embosser left its imprint (it does so at room temperature) there was no indication of the sleeve melting or becoming welded together.

- Next we heated the sleeve in a controlled temperature oven to ~230 degrees for 10 minutes and applied pressure. We had the same results as step one.

- Then we heated the sleeve in the oven to 300 F for 10 minutes. Here we experienced much different results. The LDPE began to curl and actually welded itself together without any outside pressure. The embosser/vice grip sealed the two sides of the bag together.

- Finally we reduced the oven temperature to ~260 F and heated the LDPE material. There was some bag deformation and welding but to a lesser degree than 300 F. When pressed between the embossing plates the two sides of the sleeve solidly welded together at the pressure point.

Conclusion:

HydraSleeves can be used in geothermal applications not exceeding ~230 degrees Fahrenheit. They should even withstand a good amount of external pressure even at this temperature. If dissolved gasses (steam) are anticipated the sleeve needs to be vented at the top to allow the expanding gas to escape during recovery.

Please call 800-996-2225 or email This email address is being protected from spambots. You need JavaScript enabled to view it. if you have any questions.