Early in 2016 we received several calls and emails on using HydraSleeves to sample PFA's (Perfluorinated Compounds). We were provided with a list of items that are, and are not, acceptable for PFA sampling sites. We were surprised to see LDPE (the original HydraSleeve material) was on the non-compliance side of the list.

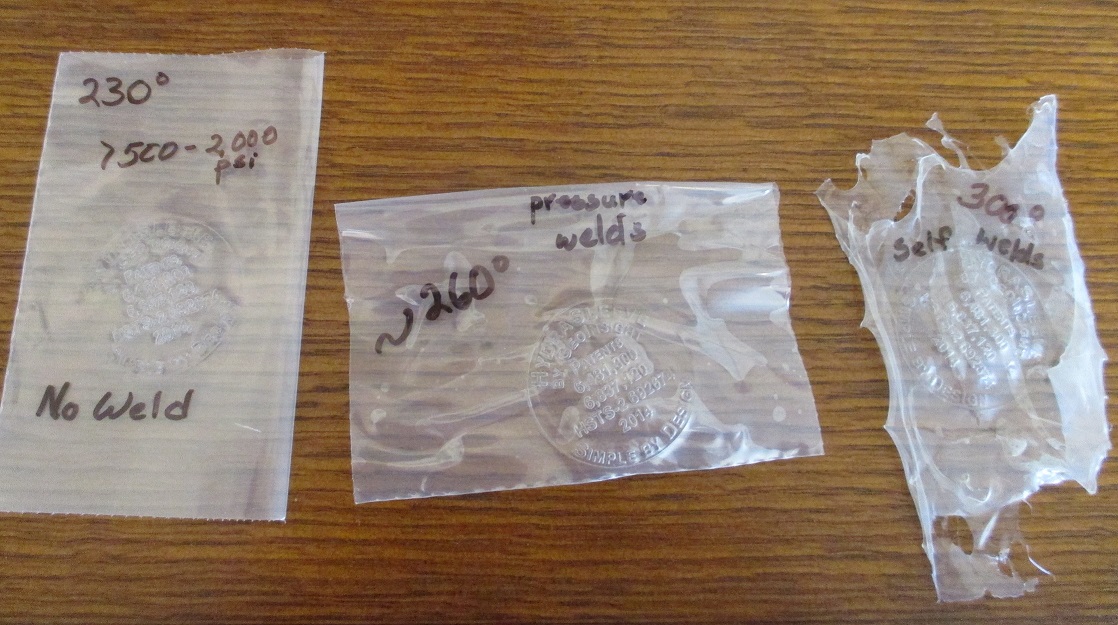

Polypropylene and HDPE are on the acceptable side; so we set out to make a version of our HydraSleeves from HDPE material.

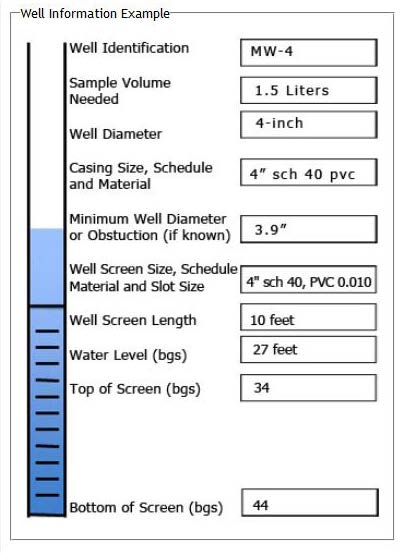

The HDPE version of HydraSleeves available in 2 sizes; they are made for 2-inch wells; and they are in the Super/SkinnySleeve configuration.

PFCHDSS-1L $21.00

PFCHDSS-2L $26.00

These same sleeves can be used for 4-inch wells and larger diameters by using the wide mouth adapters availabe in 4-2 inch reducer for 4-inch wells or the SWA adapter for surface water or 6-inch wells and larger.

Because of the SuperSleeve configuration, they will require a threaded PVC top collar (or a wide mouth adapter) or threaded top weight. See links to the accessories on the product ordering page above.

Along with the sleeves, we also have to accommodate for new packaging and handling materials, as our current packaging is also made of LDPE. The sleeves will be packaged in ultra-clear Polypropylene Ziploc bags with no writing on them. Weights shipped with the orders will be sent in woven Polypropylene bags (similar to sand bags). Our original dispensing straws are already Polypropylene, so they are acceptable as is.

Please This email address is being protected from spambots. You need JavaScript enabled to view it. or call 800-996-2225 if you have any questions.

yes, they have actually worked for some geothermal applications in South American of which we are aware.

yes, they have actually worked for some geothermal applications in South American of which we are aware.