The use of no-purge samplers, like the HydraSleeve, is arguably the fastest growing segment of the groundwater monitoring market. Tens of thousands of samples are collected each year using no-purge sampling devices. Why? It provides formation quality samples using a much simplified and repeatable groundwater sampling method, resulting in dramatically reduced field time and expense. In addition, it is a less energy intensive method of collecting groundwater samples, producing a smaller carbon footprint than conventional sampling methods.

The following constitute the top three questions we get pertaining to the HydraSleeve.

1) WHAT DO THE REGULATORS THINK?

HydraSleeve and Passive Diffusion Bags have been used in all 50 states, Canada and overseas. There are a few states that may recommend either well-volume purging or low-flow methods in their guidance, but they still do not exclude no-purge sampling. There are no states that specifically prohibit the use of any no-purge (passive) sampling technology.

The regulatory approval climate is changing. The Kansas Department of Health and Environment (KDHE) has developed a "Sampling and Analysis Plan Development for Industrial Landfills "technical guidance document", which discusses the proper use of the HydraSleeve no-purge sampler.

Conversion to no-purge sampling methods is typically examined on a site-by-site basis. Usually this entails an initial round of no-purge sampling, the results of which are compared with the results from the site's previous sampling method. The comparison of data from the two methods is used to determine if no-purge sampling meets the site's data quality objectives.

HydraSleeve simplicity and low cost enables the user to conduct a comparison study easily, inexpensively and efficiently. If the HydraSleeve results are compared to historical data, cost savings of 50%-80% can be immediately recognized.

Please follow this link to see the results of our state-by-state research in map format. This link shows which states have included HydraSleeve technology in their guidance documents and which states approve no-purge methods on a site-by-site basis. It also shows that HydraSleeves have been used in all 50 states.

2) HOW DO I SOLVE PROBLEMS WITH SAMPLE VOLUME USING A NO-PURGE SAMPLER? HOW DO I GET MORE VOLUME FROM MY NO-PURGE SAMPLER?

By definition, no-purge sampling devices are restricted to collecting the volume of fluid contained within the well screen. For example, a 2-inch well with a 10-foot long saturated screen has an absolute maximum of 6.4 liters (1.6 gallons) of water available for no-purge sampling.

In response to the sample volume issue, GeoInsight has developed a sampler which will collect the most water available from a 2-inch (schedule 40) well. This new device, developed in the summer of 2009, the HydraSleeve SS, has almost doubled the amount of water that could be collected out of a 2-inch well as compared with earlier designs of the HydraSleeve. Prior to the development of the HydraSleeve SS, only about 45% of the available water could be captured from the well screen. Using the HydraSleeve SS, up to 80% of the available water in the well screen can be collected as sample. This is very important for 2-inch wells with a short screened interval or a short water column within the screen.

Due to continued requests for even more than 2 liters of sample volume we have developed an even larger SuperSleeve. We call it the TurboSleeve. It will collect 4 liters of sample volume from a 10-foot screen. Please read the white paper and field instructions for more information on the TurboSleeve.

Another option for ensuring that you have sufficient water for all of your analytical needs is to check with your laboratory to see if they really need as much sample volume as they request. Most laboratories ask for 2 to 4 times as much sample as they need, so they can actually work with much less than they initially asked for. The table below illustrates just how skewed the lab-requested volume vs. the accepted minimum volume can be:

|

Minimum Sample Volumes for Common Environmental Analytical Methods |

||

| Parameter | Asked for | Accepted Minimum Volume for one Analysis |

| Alkalinity | 200 (mls) | 10 (mls) |

| Hex Chromium | 300 | 5 |

| Perchlorate | 50 | 25 |

| Total Hardness | 100 | 10 |

| VOC's | 140 | 20 |

| BNAs | 1000 | 250 |

| Pesticides | 1000 | 100 |

| PCBs | 1000 | 100 |

| Total | 3790 | 510 |

For your convenience we are providing a minimum sample volume requirement spreadsheet for you to use as a guideline to negotiate sample volumes with your lab. To download the Excel spreadsheet, please click here.

This spreadsheet was developed by Columbia Analytical Services Inc in conjunction with the ITRC. They are a full-service analytical laboratory testing network, with locations across the United States. They were part of the original ITRC Passive Sampling Team that organized a panel of well known laboratories to agree on the absolute minimum volumes that were necessary for a wide variety of analytical methods in response to the sample volume limitations of the passive sampling devices. Columbia Analytical also has extensive experience with limited volume samples including those taken with passive sampling devices. You may contact them directly, two contacts are shown below, or visit their website at www.caslab.com

Dee O'Neill 360-577-7222 This email address is being protected from spambots. You need JavaScript enabled to view it.;

Mark Wilson 585-749-0934 This email address is being protected from spambots. You need JavaScript enabled to view it.

3) WHY DON'T MY RESULTS COMPARE IN ALL THE WELLS?

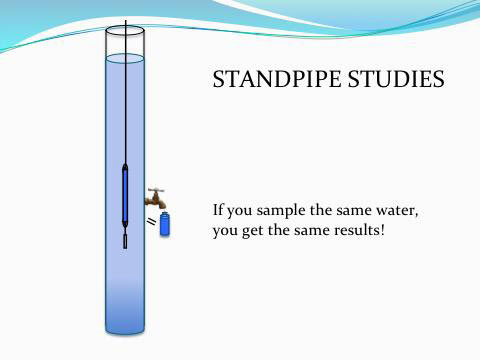

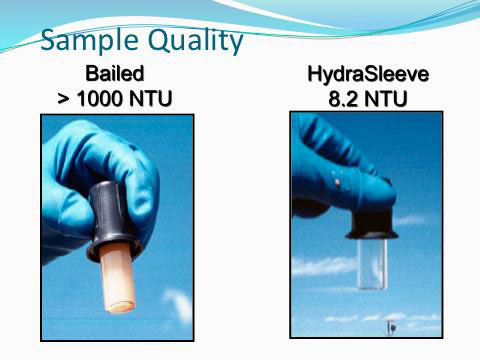

In the majority of wells, results from samples collected with the HydraSleeve (as well as other no-purge samplers) will compare favorably with results from samples collected with traditional sampling methods (i.e. well-volume purging and low-flow purging). Some samples may have slightly higher concentrations and some slightly lower concentrations. However, in a few wells, some samples may not compare very well at all. In almost all of these cases, this is due to the inherent differences between low-flow sampling, well-volume purging and no-purge sampling and the resulting source of the sampled water.

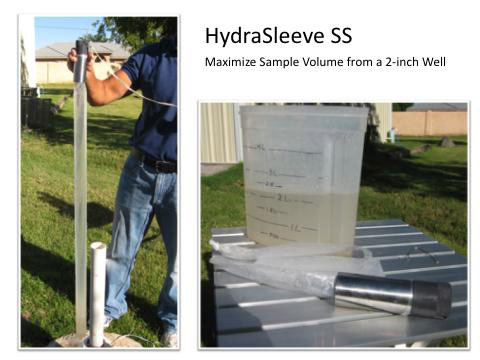

Standpipe studies conducted by Parker and others in 2002 demonstrated that no-purge samplers (HydraSleeve included) produced statistically similar results in a spiked standpipe when compared to results from samples collected from a discharge spigot at the same depth. Similar investigations done at the Stennis Space Center under the EPA Environmental Technology Verification Program compared low-flow pumping systems and no-purge sampling devices to control samples collected in a 100-foot long standpipe. Again, the results compared favorably with the control samples.

In short, if you sample the same water you get the same results.

No-purge devices only sample water flowing through the screen under ambient (undisturbed) conditions. They collect a sample from a defined vertical and horizontal interval within the well screen. As a result, no-purge sampling is a very precise and repeatable method for simply and inexpensively collecting groundwater samples. In contrast, well-volume purging and low-flow sampling induce flow into the well from zones above and below the well screen as well as from an undefined horizontal interval adjacent to the well. Depending on the geology of the formation surrounding the well screen, well-volume purging (and, low-flow sampling) can pull water into the screen from substantial distances away from the well, water that would not ordinarily be entering the well screen under ambient flow conditions. The difference in the origin of the sample (within the screen, from above or below the screen, from formations adjacent to the screen) is the primary reason differences are occasionally seen between no-purge sampling results and well-volume purging or low-flow results.

Normally, no-purge samples will provide results more similar to low-flow samples than well-volume purging, because low-flow sampling disrupts the ambient ground water flow regime less than well-volume purging.

Occasionally, when using a no-purge sampling device in or near a contaminant source or smear zone, contaminants that have a tendency to attach to soil particles or exist as microscopic colloids will have lower concentrations in no-purge samples than in purged samples (Zemo 2006). Purging, particularly with a bailer, has a tendency to agitate the water column in the well and the formation materials adjacent to the well screen and mobilize particles that are not normally mobile in the groundwater system, resulting in elevated concentrations of contaminants (like BTEX) when compared to no-purge samples. The same phenomenon has been seen when comparing low-flow samples to samples collected using well-volume purging.