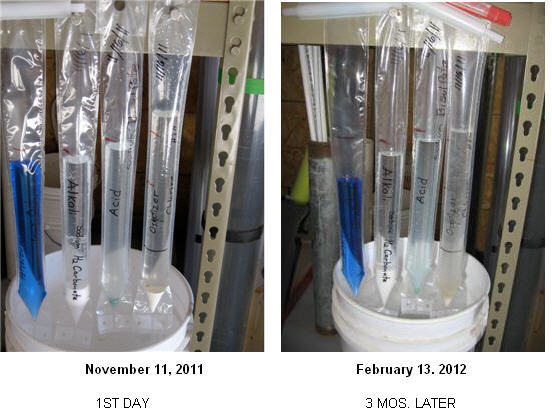

Well it's been a little bit more than a year since we began a documented chemical resistance experiment. We first reported this with commentary on the fact that you can "Leave a Sleeve". Some have expressed concern in leaving a HydraSleeve in a well for an extended period of time. We have found now even a year later that there is no deterioration of the sleeves even when filled with pure, very aggressive, chemical contaminants.

Here's the comparison photo from February 2012:

And now the current November, 2012 photo:

Last February we reported:

|

"The blue liquid is a petroleum based product, next is alkali, then acid and finally chlorine as an oxidizer. An interesting thing happened with the blue petroleum additive. The amount of liquid remaining has decreased significantly due to the diffusion of the contaminant through the sleeve wall and into the air - it is not a result of deterioration in the HydraSleeve. None of these sleeves shows any sign of wear or weakening of the material." |

The continued diffusion of the volatile compounds through the wall of the sleeve has significantly lowered the level of the petroleum based product. So, we added some water to fill this particular bag to show that it has not leaked. Over an extended period of time it has simply diffused through the walls of the material as would happen to a passive diffusion bag.

The chemical resistance of the HydraSleeve material is not an issue when leaving the HydraSleeve in a monitoring well for any length of time. Prior to this experiment we had placed a HydraSleeve under lamp oil for several years and just as in this experiment, no degradation of material occurred.

Please call 800-996-2225 or This email address is being protected from spambots. You need JavaScript enabled to view it. with any comments or questions.

call (575-526-3381) if you ever need environmental drilling or well installation done in the Las Cruces area.

call (575-526-3381) if you ever need environmental drilling or well installation done in the Las Cruces area.

If you can't totally curb your purging, ease your way into no-purge sampling by trying the HydraSleeve along with other sampling methods.

If you can't totally curb your purging, ease your way into no-purge sampling by trying the HydraSleeve along with other sampling methods.